Synthesis and applications of porous semi-conductors

Porous materials present very different properties (electrical, optical, chemical etc…) than massive materials. Those new properties are principally a result of their texturation at a nanometre scale. Our lab seeks to develop new applications of those materials in microelectronics devices (electric isolation under RF devices, anisotropic structures by electromechanical etching for 3D devices, electrical isolation around AC switches, porous wide band gap semi-conductors for sensors) or energy micro-sources (hydrogen diffusion layers for Ion Exchange Membrane micro Fuel Cells Lithium Micro-batteries anodes, micro-supercapacitors electrodes).

Our team focuses on two porous semiconductors: silicon and silicon carbide.

Startups

Achievements

Porous Silicon

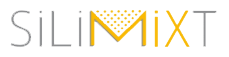

Porous Silicon (PS) is a nanostructured material, able to answer nomad electronic requirements: high density power sources, high efficiency analogic functions… It is formed by electrochemical etching (anodic dissolution) of crystalline silicon wafers in hydrofluoric acid based electrolytes. According to the substrate doping, the crystalline orientation, the electrolyte composition and temperature or the anodisation conditions (applied current, duration, etc…), various morphologies can be achieved. The pore dimensions vary from a few nanometers to several micrometers as seen. below.

Porous silicon classification, from microporous to macroporous in function of the average pore diameter (Ø).

Porous Silicon Carbide

Porous wide bandgap semi-conductors such as silicon carbide (SiC) can also be achieved leading to various morphologies:

Morphologies of porous SiC achievable by electrochemical etching (from G. Gautier et al., Nanoscale Research Lett., vol. 7, pp. 367-373, 2012).

Recent work

Some recent example of achievements involving porous silicon can be mentioned. The highest specific surface area ever measured for porous silicon (1125 m²/g) was reached using new HF electrolyte compositions [A. Loni et al., in J. of Solid State Science & Technology, Vol. 4, No 8, pp. P289-P292, 2015]. These particles are highly photoluminescent [J. Joo et al. , in Applied Physics Letters, Vol. 108, 153111, 2016]. This work was performed in collaboration with Pr Leigh Canham (UK) and Pr Michael Sailor’s group in San Diego.Backing layer of transducers integrated on silicon.

Photoluminescence of PS particles under UV light.

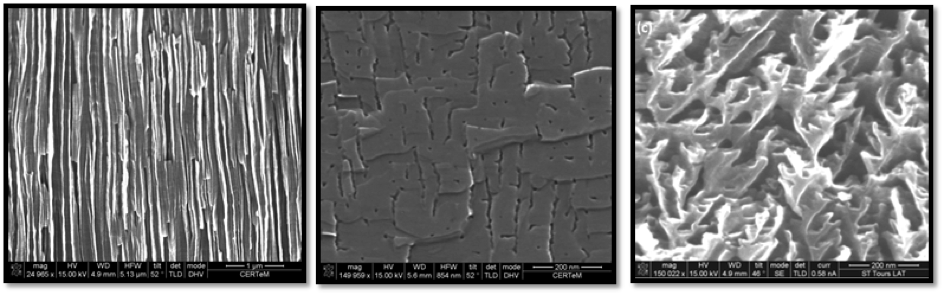

The first realization of a hybrid porous silicon/silicon substrate for RF applications was achieved [M. Capelle et al., in Appl. Phys. Lett. 104 pp. 072104-1-4, 2014]. This work was done in collaboration with STMicroelectronics Tours on 6 and 8 inch silicon wafers. These substrates lead to significant performance enhancement.

RF circuits prototypes integrated on silicon / PS hybrid substrates. a) Common mode filter and ESD protection diode. b) Low pass filter and ESD protection diode. Components commercialized by STMicroelectronics.

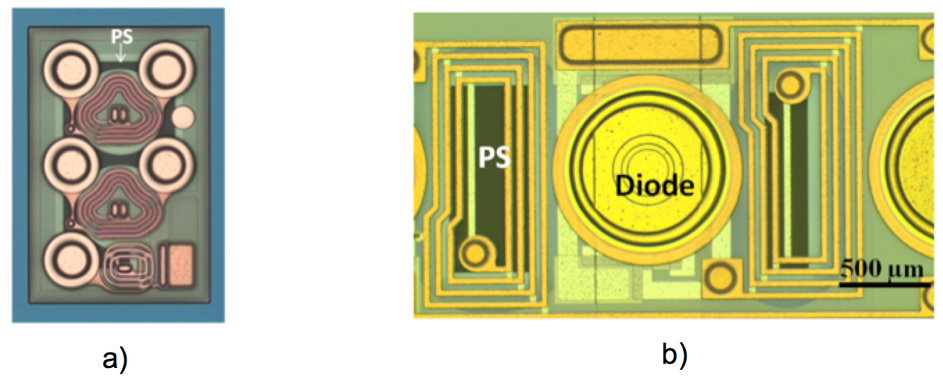

We also investigate a PS-based edge termination for planar type AC switch. TRIAC device prototypes, specifically dedicated to evaluate blocking performances, were crafted by integrating electrochemical etching in device processing. A mixed porous morphology containing micro-, meso-, and macropores can be obtained in a p-Type through-wafer-diffused via after anodization. Low leakage currents (<10 μA) have been demonstrated up to several hundred volts for both bias polarities [In B. Lu et al., IEEE Trans. on Electron Devices, vol. 65, No 2, pp.655-659, 2018].

(a) TRIAC with porous silicon peripheries on 6 inch Si wafer.

(b) Optical microscope top view of a TRIAC with porous silicon peripheries.

(c) Schematics of a TRIAC cross-section.

(d) SEM cross-sectional view of porous silicon periphery.

I–V characteristics of TRIAC prototypes with PS-based edge termination.

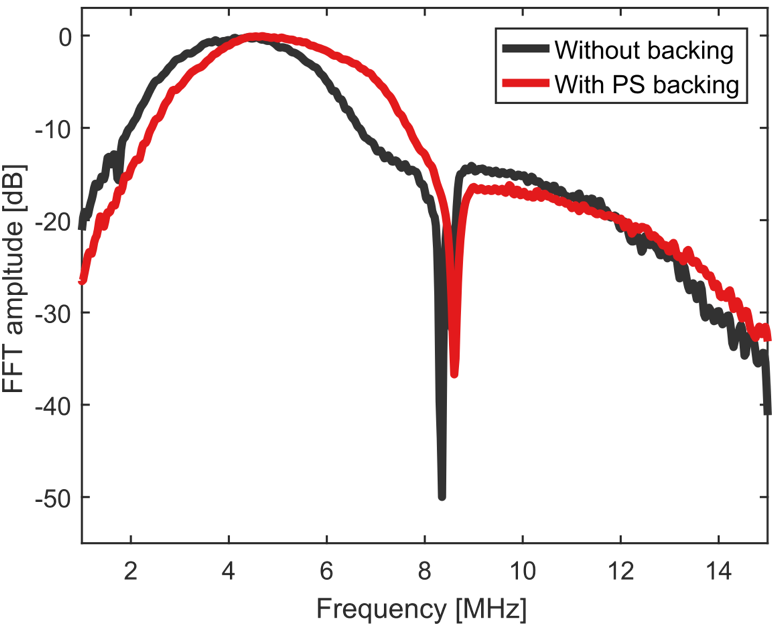

The potential of PS film integration on the rear side of ultrasonic transducers to enhance the device performances has also been investigated. Indeed, a part of the energy is transferred to the transducer silicon substrate during the ultrasound emission. This phenomenon leads to wave propagation in the substrate which creates spurious oscillations in the output acoustic signal. Hereby, porous silicon layers were etched on transducer’s opposite sides in order to absorb a part of the propagated waves. The influence of the thin film on the substrate resonance was investigated by the electro-acoustic responses of the transducers integrated on both silicon and silicon/porous silicon substrates. We showed that a porous silicon layer as thin as 60 µm-thick helps to damp the substrate resonance and shifts its resonance to higher frequencies [J. Lascaud et al., in Ultrasonics, Vol. 96, pp 196-200, 2019].

More informations on acoustic behaviour of ultrasonic transducers in the GREMAN can be found here.

Structure of the CMUT with a PS backing.

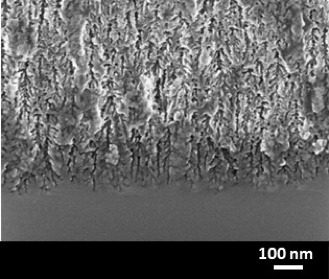

SEM cross-section showing the morphology of the mesoporous layer.

Transducer's electroacoustic response.

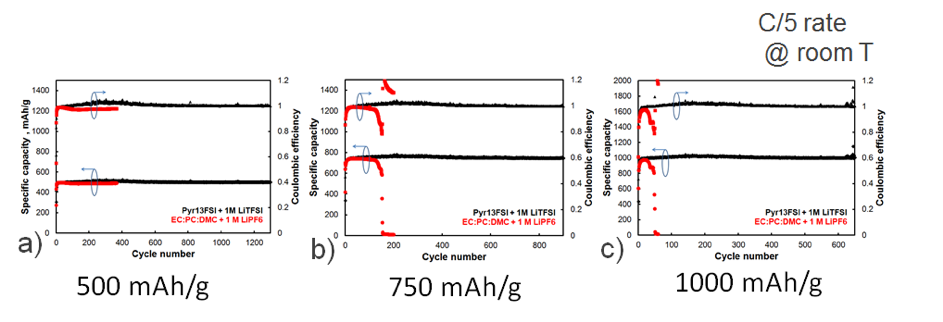

Flexible macroporous silicon negative electrodes were also performed. High cycling performances were measured when using ionic liquids as electrolyte [E. Luais et al. in Journal of Solid State Electrochemistry, Vol. 23, No 3, pp 937-941, 2019] (work performed in collaboration with PCM2E lab).

Macroporous silicon electrodes for Li-ion microbatteries cycling performances.

Macroporous silicon electrodes for Li-ion microbatteries as seen microscopically and macroscopically.