Vibration energy harvesting

Electronics has developed rapidly over the last three decades, notably through a reduction in the consumption of components and their miniaturisation. The continuous reduction in consumption to achieve the same function has made it possible to envisage completely autonomous electronic devices. The question of energy autonomy has been accompanied by the appearance of a new field of activity, ambient energy harvesting, namely the conversion of part of the energy available in the immediate environment of the system to be powered. This energy is mainly solar, thermal or mechanical. Using an energy harvesting system coupled with a storage element increases the degree of energy autonomy of the latter.

Thus, since the early 2000s, energy harvesting has become a new application area for piezoelectric materials, as these materials offer the advantage of direct conversion of mechanical energy into electrical energy. PZT is the most widely used material in industry for piezoelectric transducer or sensor applications. However, the health and environmental problems raised by this material, particularly during its shaping and recycling, have led to intense research into lead-free piezoelectric ceramics, which will comply with the European REACH directives, whose restrictions on lead will most likely be tightened. There are currently different families of lead-free piezoelectric materials, and among them, the derivatives of barium titanate (BaTiO3 or BT) and the derivatives of potassium sodium niobate (KNbO3 or KNN). Although discovered and studied since the early 1950s, the popularity of these compounds has really developed over the last fifteen years, in response to advances in REACH legislation. To date, numerous compositions from BT and KNN, with a wide range of properties, have been studied. GREMAN currently has 3 partnerships with institutes studying and producing lead-free piezoelectric materials, which are studied by GREMAN to include them in future vibration harvesting devices.

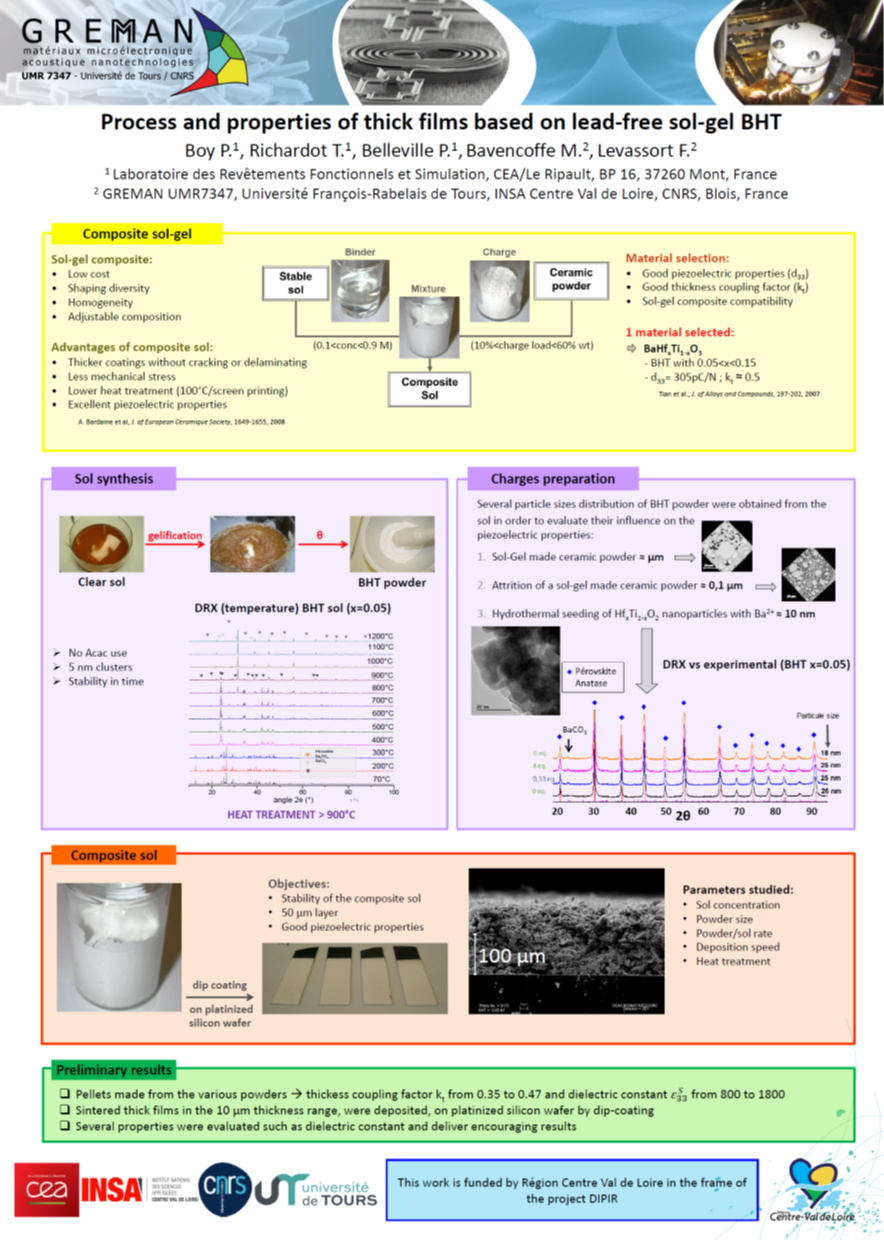

- CEA/Le Ripault, south of Tours, has been developing for several years a process for depositing piezoelectric thick films of hafnium-doped barium titanate (BaHfxTi1-xO3 or BHT) using a composite sol-gel process. The DIPIR regional project brings together the research teams of GREMAN, CEA/Le Ripault and VERMON SA to collaborate actively on the fabrication, characterisation and implementation of these lead-free piezoelectric thick films in vibratory energy harvesting devices in order to evaluate their performance and compare them to those incorporating piezoelectric materials with lead.

- The Electronic Ceramics Department of the Jozef Stefan Institute in Ljubljana (Slovenia) has world-renowned know-how in the field of the fabrication and shaping of new piezoelectric materials. Through a PHC PROTEUS project, GREMAN and Jozef Stefan Institute are collaborating on the fabrication, characterisation and implementation of piezoelectric thick films (of PMN-PT type), developed using an innovative low-temperature sputtering technique. This process, once optimised, makes it possible to minimise the manufacturing stages and reduce costs, thus presenting real prospects for industrialisation. Two types of sectors are targeted: the production of piezoelectric energy recovery devices for connected and autonomous objects, and the production of transducers operating at high frequency for high-resolution ultrasound imaging.

- The Institute for Research on Ceramics of the University of Limoges (IRCER UMR 7315) and the Centre for the Transfer of Ceramic Technologies (CTTC, Limoges), are developing thick layers of lead-free piezoelectric materials based on sodium bismuth titanate (Na0.5Bi0.5TiO3) on metal substrates, by the aerosol deposition method (ADM). Their potential for vibrational energy harvesting is being evaluated by GREMAN.

RESULTS/COMMUNICATION for ANR LabCom project « Lab-TMEMS »

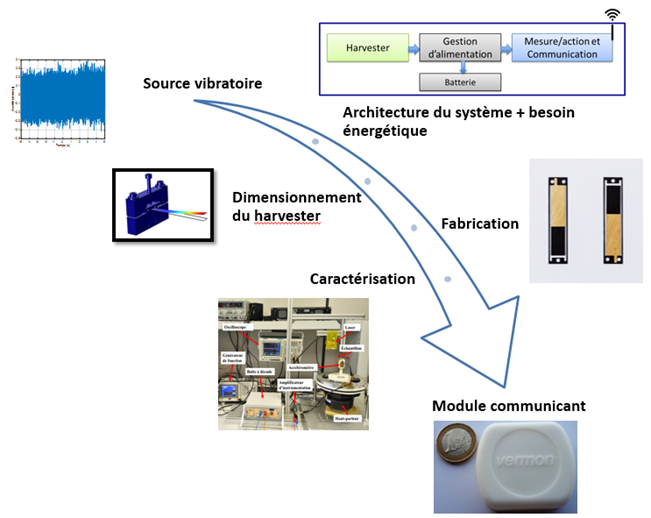

Within the framework of Lab-TMEMS joint laboratory (ANR LabCom project 2014-2017), GREMAN laboratory and VERMON SA company have worked on piezoelectric devices for vibrational energy harvesting in specific environments (industrial, medical, etc.).

Thesis of Thien HOANG "Piezoelectric energy harvesting device: modelling, fabrication and characterisation [https://hal.archives-ouvertes.fr/tel-03216575v1]

Cantilever-type piezoelectric generators for vibrational energy harvesting (unimorph and bimorph structures) :

Specifications :

- Vibration :

- Low acceleration (# 1 g)

- Low frequency range (< 200 Hz)

- Device characteristics :

- Compact, light (< 1 cm3)

- Long lifetime (> 15 years)

Design approach for a self-powered communicating module :

Main results :

- Hybrid analytical 1D – FEM 3D model :

- Determination of the effective model parameters

- Validation at low frequency and low acceleration (5mg) : accurate estimation of harvested power (85 % gain on accuracy)

- Optimisation of geometrical parameters for given specifications :

- Power delivered by the optimal device : 36 nW @ 5 mg, 132 Hz

- Power density: 27 mW/cm3/g2 @ 132 Hz

- Guidelines for the harvester design

- Demonstration for industrial and biomedical applications

Communications :

[1] Hoang T, Ferin G, Rosinski B, Bantignies C, Le Khanh H, Nguyen-Dinh A, et al. Characterization of a thin piezoelectric material before integration into a cantilever-based mechanical energy harvester. IEEE Int. Ultrason. Symp. IUS, vol. 2016- November, IEEE Computer Society; 2016. https://doi.org/10.1109/ULTSYM.2016.7728652.

[2] Hoang T, Poulin-Vittrant G, Ferin G, Levassort F, Bantignies C, Nguyen-Dinh A, et al. Parametric study of a thin piezoelectric cantilever for energy harvesting applications. Adv Appl Ceram 2017. https://doi.org/10.1080/17436753.2017.1403538.

[3] Hoang T, Poulin-Vittrant G, Ferin G, Levassort F, Bantignies C, Nguyen-Dinh A, et al. Modeling Of The Clamping Fixture Of A Piezoelectric Cantilever-type Energy Harvesting Device. COMSOL Conf., 2017. https://www.comsol.fr/paper/modeling-of-the-clamping-fixture-of-a-piezoelectric-cantilever-type-energy-harve-50541.

[4] Hoang T, Bavencoffe M, Ferin G, Levassort F, Bantignies C, Nguyen-Dinh A, et al. Modeling and Electrical Characterization of a Cantilever Beam for Mechanical Energy Harvesting. IEEE Int. Ultrason. Symp. IUS, vol. 2018- January, IEEE Computer Society; 2018. https://doi.org/10.1109/ULTSYM.2018.8579676.

[5] Hoang T, Ferin G, Bantignies C, Rosinski B, Vince P, Nguyen-Dinh. Aging assessment of piezoelectric energy harvester using electrical loads. J Phys Conf Ser 2018;1407:12078. https://doi.org/10.1088/1742-6596/1407/1/012078.

[6] Hoang T, Bavencoffe M, Poulin-Vittrant G, Ferin G, Levassort F, et al. An efficient tool for modelling piezoelectric cantilevers used for mechanical energy harvesting. Frontiers in Nanomaterials for Energy Harvesting and Storage, Le Studium Conferences ; 27-29/8/2018, Tours, France.

RESULTS/COMMUNICATION of « DIPIR » regional project

Poster @10th International Conference ‘Electroceramics for End Users X - PIEZO 2019’, 27-30 Jan. 2019, Czech Republic